“In-Nuccalijiet”

“In-Nuccalijiet”

The human eye is one of the most vulnerable and exposed organs in our body. Most of the other organs are protected behind the human skeleton, however, the eye only has the eyelids and the eyelashes as natural protection. In conjunction with our natural reflex to blink our eyelids protect our eyes from dust, wind, intense light and small flying objects such as insects.

However, this protection is natural and only protects against natural sources of harm. At the workplace, we have several industrial processes which bypass such natural protection due to their excessive speed, forces, radiation and/or light. It is often observed that grinding, rock breaking, metal work, polishing, lathework and other work processes which may create flying particles or intensive radiation/light (such as welding) are carried out without the required collective protection.

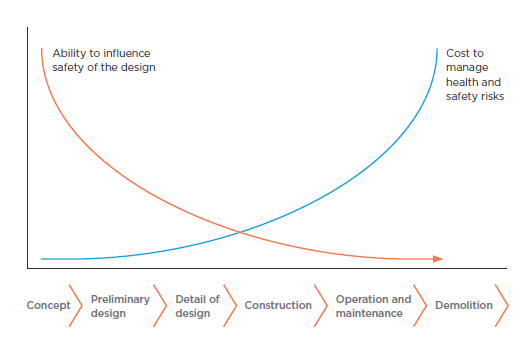

Usually, the first thing that comes to mind as protection for the eyes is safety glasses. However, as per the hierarchy of controls in health and safety, these are the last item to consider when implementing control measures. Safety glasses offer only individual protection and should they fail, they do not fail to safety, meaning the individual will be harmed. Other collective protective measures should be considered prior to the provision of safety glasses.

We’ll be using a pipe-cutting machine as an example to outline what some of these measures are.

- Elimination: Is it possible to remove the process of using the pipe-cutting machine? For example by purchasing pipes of the correct length?

- Substitution: Is it possible to change your equipment or process to use lesser hazardous equipment? Will a hand operated pipe cutter do the required work?

- Engineering Control: Does the machine has the required guards to make sure that in case of failure the hazard does not reach the user? Can the machine be completely isolated from the worker by enclosing it?

- Administration controls: Is the pipe cutting machine subject to a periodic maintenance regime? Have the personnel been trained on the use of this equipment? Are safety signs posted and rules implemented?

After considering the above, PPE is to always be implemented when using industrial high-risk equipment. All the above-mentioned measures reduce the risk significantly, but some residual risk will always remain as we can never be completely safe and this is mitigated by PPE, more specifically safety glasses in this case.

Different types of eye protection are available depending on the hazard one needs to protect against. Amongst others, these include safety glasses, safety goggles, hood and face shields.

The type of eye protection made available to the employees should be based on a risk assessment, based on manufacturer guidelines and certification.

The main types of certification for safety glasses are EN166 (European standard) and ANSI Z87.1 (American standard). Such certification would be outlined on the safety glasses frame and also on the lenses.

For employees who wear prescriptive glasses, there are two options, either safety over-glasses or prescriptive safety glasses. Over glasses, as the name implies, are safety glasses which are designed to be worn over normal prescriptive glasses. Prescriptive safety glasses are specifically designed safety glasses which have integrated certified prescriptive lenses.

Regardless of the type of safety glasses chosen, it should always be ensured that these are manufactured to the previously mentioned standards. I have come across situations where suppliers provide frames which are certified but fitted with normal non-certified prescriptive lenses. Personally, I do not accept or recommend these types of glasses within my workplace and practice the rule “no certification means not allowed”.

For any equipment to be certified, this has to be manufactured according to a standard, as such the only local shops which provided these prescriptive safety glasses are PPE importers who order the glasses directly from the PPE manufacturer.

When a grinder wheel is spinning up to 2000 RPM, all safety features fail and it detaches, you want to be sure that the personal protective equipment provided to the employees is certified as safety equipment. PPE is always the last line of defence.

(Picture by Gillian S: Safety Glasses Save Lives (bulksafety.com))

Have a look at the safety glasses used by yourself or at the workplace, are these adequate and certified? Are the employees who use prescriptive glasses offered the same level of protection as all other employees? Are you making use of safety glasses to reduce the level of residual risk?

“L-Immaniġjar tal-Bidla”

“L-Immaniġjar tal-Bidla”