‘Ix-Xedd’

‘Ix-Xedd’

Safety Harnesses are used whenever work at heights is carried out. They are part of a system implemented to ensure the safety of workers and to prevent injuries from falls. Although the use of safety harness is taking an upward trend in Malta, it is often observed that these are used incorrectly. To determine the effectiveness of the harness, the whole system has to be looked at.

There are two fall prevention systems which can be used, fall restraint and a fall arrest system. The difference between the two is, that one will stop you from ever going over the edge (fall restraint) and the other will let you fall but stop you from touching the ground (fall arrest). All systems has 3 main components, the safety harness, the anchorage and the connector.

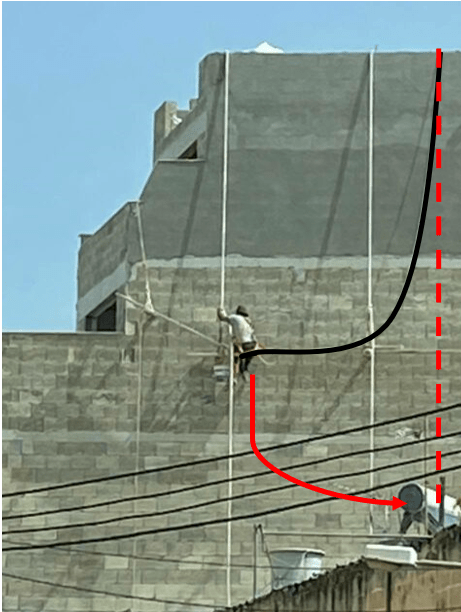

On March 21st I took the picture hereunder at Bugibba. Is it safe to assume that the worker is safe just because he has donned the harness?

What do the guidance and legislation say on the different equipment used in fall prevention systems?

The Harness

A harness is to be inspected prior to each use to ensure that there are no damages in the shackles and straps. All straps are to be adjusted, tightened and fastened depending on the user. The harness should be tight enough to allow a flat hand to fit between the straps and does not allow the flat hand to form a wrist (Inspecting fall arrest equipment made from webbing or rope, 2002).

Zooming onto the worker, one notices that he does not have the leg straps fastened and the harness is just worn over the shoulders.

Unfastened straps may lead to the body slipping right out of the harness in case of a fall, rendering the harness completely useless. Leg straps which are too loose may cause the body to exert excessive forces in a fall at the place where the straps meet the body, which may lead to bodily damages.

The Anchorage

Anchor points are to be selected and specific to the type of work being carried out. Such anchor points are to be certified for this purpose and easily identifiable. The lack of provision of dedicated anchor points may lead to the usage of ones with inadequate strength or not fit for purpose (“Fall Protection – Anchors : OSH Answers”, 2021).

The anchor point in the picture introduces a risk of swinging to the worker should he fall. The point is to be directly above the worker for maximum effectiveness. Observing the edge of the top boundary wall, it may also be possible that there is no protection from the sharp wall edge to protect the safety rope. This may lead to the rope snapping in case of a fall (Review of Work at Height Practices in the UK Broadcasting Industry, 2006).

The Connector

The lanyard connecting the harness to the safety rope needs to be chosen depending on the type of system being used. In a fall restraint system, the rope is to be fixed so as to stop the worker from ever going over the edge. While the lanyard to be used in a fall arrest system is to be integrated with a shock absorber to take up the energy which will be accumulated during the fall (“Shock absorber technology in fall arrest lanyard”, 2013). The lanyard used in the above picture cannot be observed since it is lying down on the plank in use.

The Law

The use of harnesses is mentioned in Subsidiary Legislation 424.36 Minimum Requirements at Construction Sites. Subsidiary Legislation and more specifically rope access techniques are regulated in 424.55 Work Equipment Regulations.

The legislation regulating construction sites, mentions that work at height is only to be carried out using appropriate work equipment, preferably using collective protective measures such as cradles and platforms. If the nature of work does not permit this equipment a safety harness is to be provided and used.

The Work Equipment regulation, states that when rope access techniques are used, two ropes (work rope and security rope) are to be used, tools are to be tied, an evacuation plan is to be in place and all works are to be adequately supervised.

Following this very brief observation of just one picture and a review of guidance and legislation pertaining to it, I once again raise the question, is the worker safe? could a better system be used? are workers aware of how to properly use the harness? are they aware of the dangers introduced when the same are not used correctly?